I-Sea Blue Silver Silver Ilogo Phepha Pack Packing Box Box ngesibambo seRibbon

Ukufanisa

Ibhokisi lesipho liwukupakishwa kwezipho okusebenzayo okuhlose kakhulu ukwethula izipho ezihlotsheni nakubangane ukukhombisa uthando. Kuyisandiso sezidingo zenhlalo zendlela yokusebenza esebenzayo. Ibhokisi lesipho yilona umphefumulo. Senza izipho zothando noma ukuthenga izimpahla zothando ukukhombisa ezothando, eziyimfihlakalo, ukumangala ngephakeji lephepha. Lapho uyivula kancane njenge-Vula ihlathi eliyimfihlo enhliziyweni yakho. Ibhokisi lesipho eliveza kuye ukuthi ufunani engqondweni.Lokhu kusho ukuthini ibhokisi lesipho.

Imininingwane eyisisekelo.

| Igama lomkhiqizo | Umbala webhokisi lesipho okhonjiwe | Ukuphatha okungaphezulu | Ukugcwala okucwebezelayo, ukugcwala kwe-matte, i-UV |

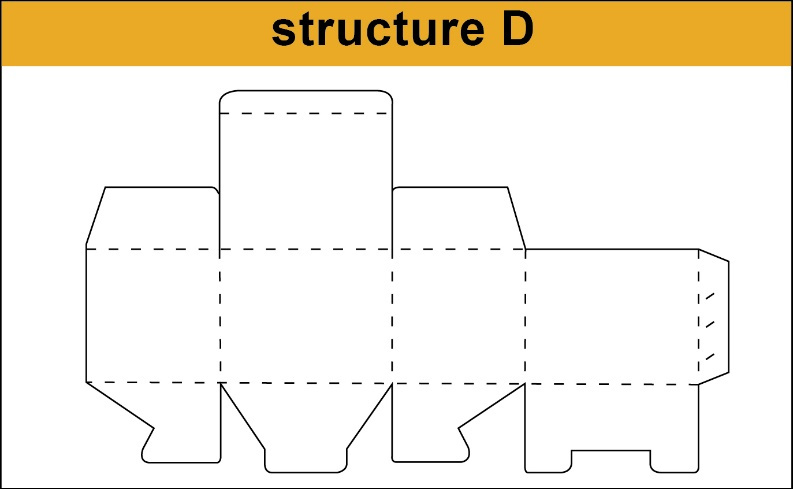

| Isitayela sebhokisi | Samba d | I-Logo Prance | I-logo eyenziwe ngokwezifiso |

| Isakhiwo sezinto ezibonakalayo | I-White Board + iphepha elihlanganisiwe + ibhodi elimhlophe / iphepha le-kraft | Ukudabuka | INingbo, e-Shanghai Port |

| Uhlobo lwe-Flute | Umtshingo, b fletter, yiba umkhupheko | Imbonakaliso | Amukela |

| Uhlobo | Unxantathu | Isikhathi sesampula | Izinsuku ezingama-5-8 zokusebenza |

| Umbala | Umbala we-cmyk, umbala wepantone | Isikhathi sokuhola sokukhiqiza | Izinsuku ezi-8-12 ZAMAHHALA ZOKUSETYENZISWA KOKUFUNDA |

| Okucindezelwayo | Ukuphrinta kwe-offset | Iphakheji Yezokuthutha | Ngamabhokisi, inqwaba, ama-pallets |

| Ukuthayipha | Ibhokisi elilodwa lokuphrinta | Hambisa | Ukwesaba komoya, ukuthwala komoya, ukuveza |

Izithombe ezinemininingwane

Ngokuthuthuka okuqhubekayo kwezikhathi, ukuvuselelwa okuqhubekayo kobuchwepheshe bokukhiqiza kanye nemishini, abantu basebenzisa ubuchwepheshe bemishini buyinkimbinkimbi kakhulu futhi isidingo semakethe sihle kakhulu, isidingo samakhadi ahlanganisiwe siyanda kakhulu. Ukuncintisana Kwezimakethe Okunamandla, Isayensi nobuchwepheshe Kuvuselelwa njalo, izinto ezintsha zokupakisha zihlala zithuthukiswa namuhla, amakhadibhodi ahlanganisiwe ukuze alondoloze izinto zawo zokufaka esimweni se- "Old Byth mfowethu kanye nokwenza ngcono isigaba soMkhiqizo Ucebe futhi ngakho-ke ukuze uthuthukise futhi uthuthukise.

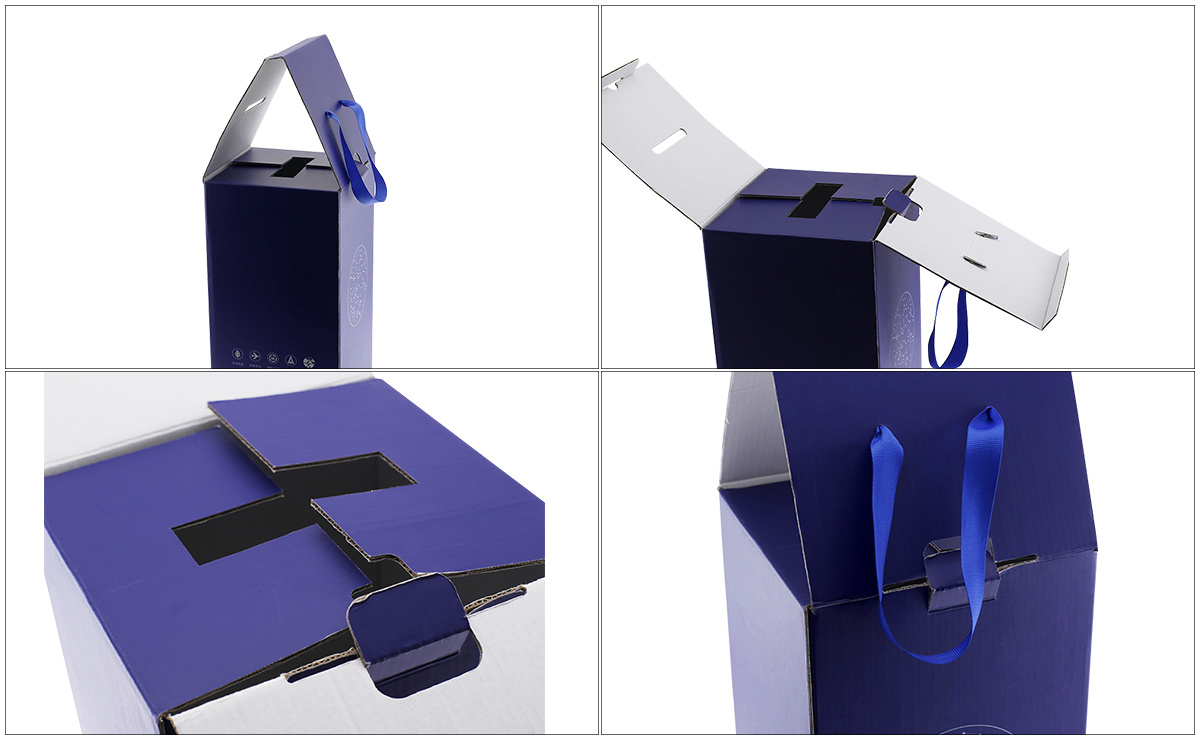

Ukwakheka kwezinto ezibonakalayo kanye nesicelo

♦ Okubonakalayo kwebhokisi lephepha nesibambo

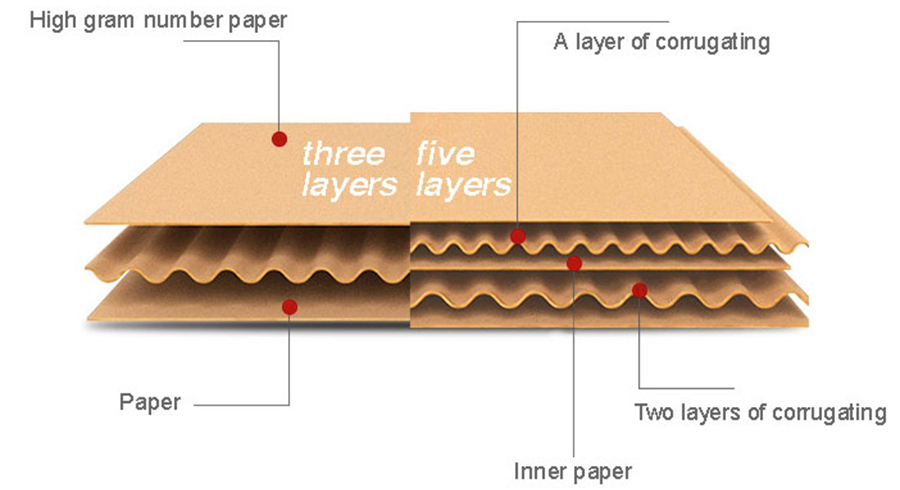

Eyaziwa nangokuthi amakhadibhodi ahlanganisiwe. Kwenziwa okungenani ungqimba olulodwa lwephepha elihlanganisiwe kanye nesendlalelo esisodwa sephepha lebhokisi lebhokisi lebhokisi (elibizwa nangokuthi ibhokisi lebhokisi), elinobuqili obuhle kanye nokunakwa. Isetshenziswa ikakhulukazi ekwenziweni kwe-carton, i-carton sandwich nezinye izinto zokupakisha zezimpahla ezintekenteke. Ukusetshenziswa okuyisisekelo kwenhlabathi ugaya uglup kanye nephepha elidonsayo ngokuphupha, kwenziwa okufanayo nekhadibhodi lasekuqaleni, bese kuthi ngemuva kokulungiswa kwemishini kugingqiwe ku-sodium siling kanye nezinye izibopho zephepha zalo.

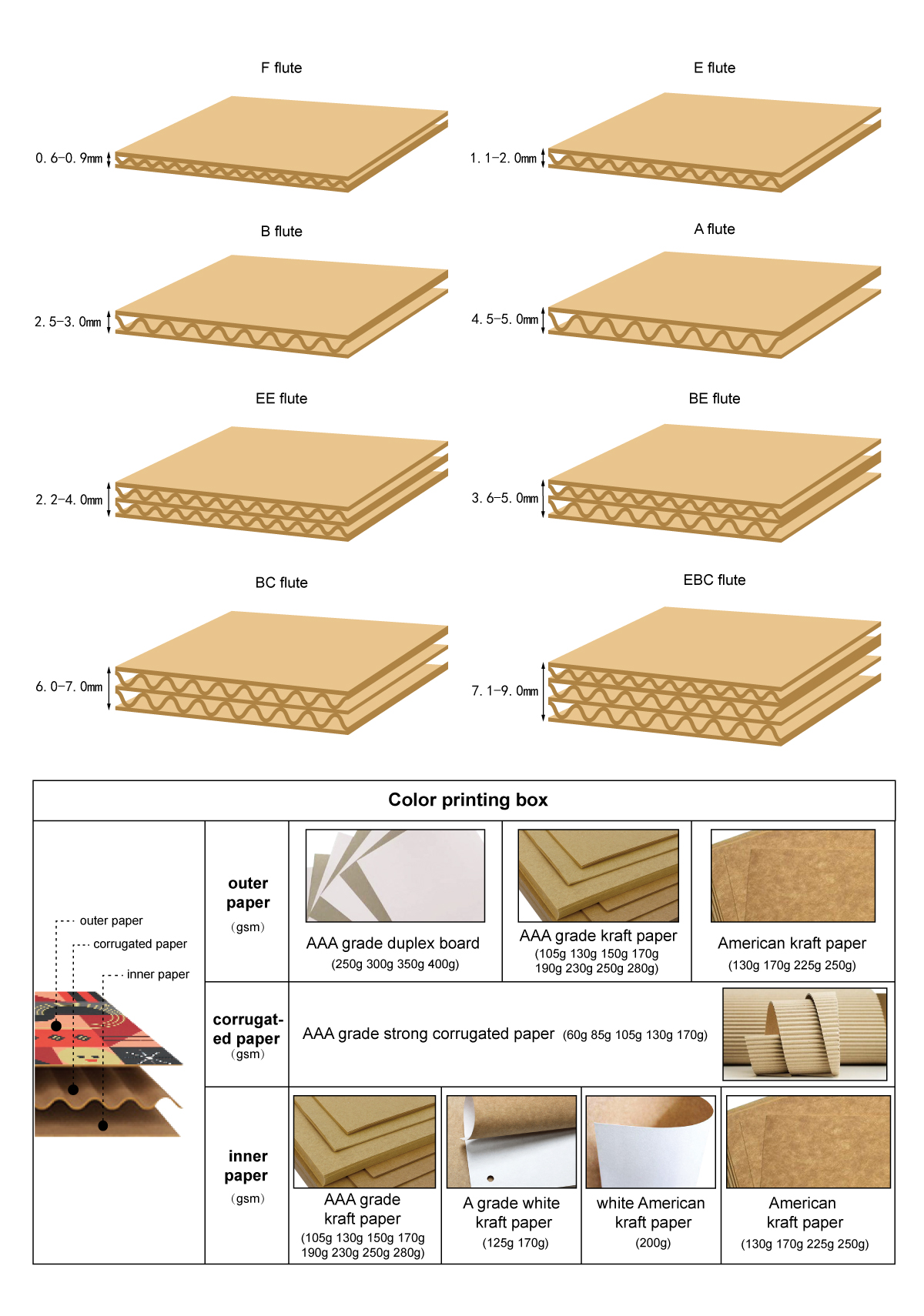

‡Iphepha elihlanganisiwe

Iphepha elihlanganisiwe lenziwa ngephepha elengise futhi lihlelwe iphepha elenziwe nge-roller procer and bonding board.

Ngokuvamile ihlukaniswe iBhodi elilodwa elilonakalisiwe kanye neBhodi Ekhule kabili ngezigaba ezimbili, ngokuya ngosayizi we-cortugated ahlukaniswe nge: a, B, C, F izinhlobo ezinhlanu.

Izicelo zokupakisha

Uhlobo lwebhokisi nokuqedela indawo

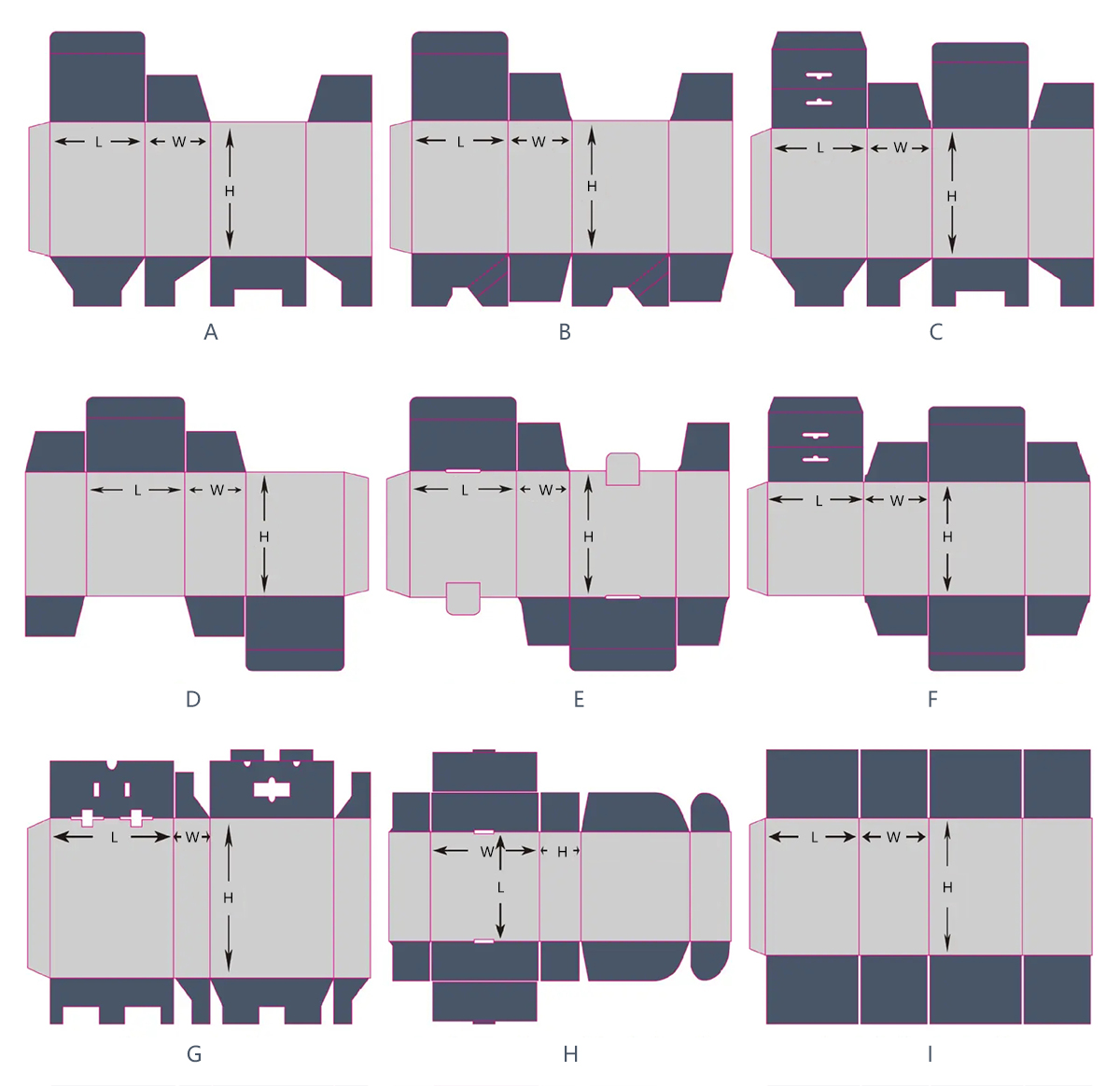

• VI-Arimes of Box Designs

I-Carton iyisimo esinezici ezintathu, yakhiwa izindiza eziningi ezihambayo, ukufakwa, ukugoqa, okuzungezwe ukwakheka kwezinto eziningi. Ingaphezulu ekwakhiweni okunezinhlangothi ezintathu lidlala indima yokuhlukanisa isikhala esikhaleni. Ingaphezulu lezingxenye ezahlukahlukene lisikiwe, lijikeleze futhi ligoqwe futhi ligoqwe, futhi ingaphezulu elitholwe linemizwa ehlukile. Ukwakheka kwendawo yokubonisa yebhokisi kufanele anake ukuxhumana phakathi komphezulu wokubonisa, uhlangothi, phezulu nangaphansi, kanye nokusethwa kwezinto zolwazi.

‡ Surfar tphendutha

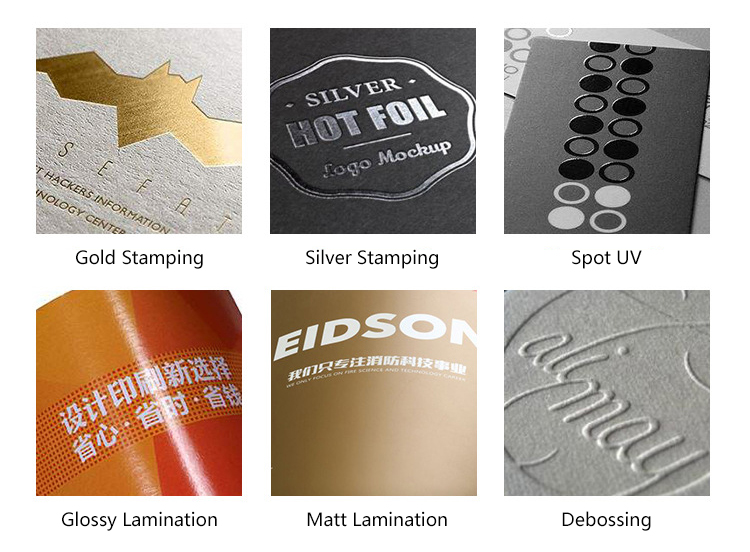

Ukwelashwa okungaphezulu kwe-Classic

❶ Isitembu segolide❷Isitembu sesiliva

Inqubo Ye-Gilding ukusebenzisa umgomo wokudlulisa okushisayo okushisayo. Ungqimba lwe-aluminium lokudluliselwa kwe-electrolytic aluminium ku-substrate ebusweniukwakha umphumela wensimbi okhethekile. Izinto eziphambili ezisetshenzisiwe e-gilding yi-foil ye-aluminium ye-electrolytic, ngakho-ke kuyabizwaI-electrolytic aluminium isitembu esishisayo.

❸Ukubusa❽ Ukubuthaka

Uhlamvu ukusetshenziswa kwesifanekiso se-concave (ithempulethi emibi) ngesenzo sokucindezela. Ingaphezulu lento ephrintiwe liyafakwaUmuzwa wokudalulwa kosizo lokudangala. Indaba ephrintiwe icindezelekile endaweni, ukuze iyeUmqondo onobukhulu obuthathu, kubangela umthelela obonakalayo.

Izici:Ingakhuphula umuzwa onobukhulu obuthathu bohlelo lokusebenza.

Ilungele Bangaphezu kwephepha le-200G, indlela yokuzwakala yendlela okusobalaiphepha eliphakeme eliphakeme elikhethekile.

Incwajana: Nge-Bronzing, umphumela wenqubo yendawo ye-UV ungcono.Uma isifanekiso se-concave ngemuva kokushisa iphepha elishisayo elishisayo, lizofinyelela umphumela wobuciko obuvamile.

❹Ukugcwala kwe-Matt ❺ Ukugcwala kancane kancane

Ukugada is Ifilimu yepulasitiki ehlanganiswe nokunamathela. Iphepha njengendaba ephrintiwe ephrintiwe, ngemuva kwengcindezi yerabha nokushisa ingcindezi ye-roller ndawonye, yakha umkhiqizo wepulasitiki.

Embozwe ngefilimu ye-matte, isendaweni yegama legama elimboziwengongqimba lwefilimu yokuthungwa yeqhwa;

Ifilimu ehlanganayo,ungqimba lwefilimu ecwebezelayophezu kwekhadi lebhizinisi.

Imikhiqizo ehlanganisiwe, ngenxa yobuso bayo ngaphezu kwengqimba yefilimu emincane futhi esobala,indawo ebushelelezi futhi ekhanyayo, umbala we-graphic ekhanyayo kakhudlwana. At ngasikhathi sinye sidlala indima yeI-materproof, i-anti-corriosion, ukugqokwa kwento, ukumelana nokungcolanjalo njalo.

❻ Spot UV

Spot UV Ingayenziwa ngemuva kwefilimu, futhi ingahle icwebezele ngokuphrinta. Kepha ukuze uqokomise umphumela we-Glazing yasendaweni, ngokuvamile ngemuva kwefilimu yokuphrinta, futhi ukumboza ifilimu le-matte.Cishe ama-80% emikhiqizo yendawo ehehayo ye-UV.